As sustainability and environmental consciousness continue to gain traction worldwide, the packaging industry is undergoing a significant transformation. One of the key sectors adapting to this change is tin box manufacturing, with companies like Huaiyang Metal Manufacture leading the way in adopting eco-friendly packaging solutions. The transition to sustainable practices in tin box manufacturing involves innovation, responsible sourcing, and the development of recyclable, reusable, and biodegradable alternatives. In this article, we’ll explore how tin box manufacturers are responding to the demand for eco-friendly packaging and what this shift means for the future of the industry.

Why Tin Boxes Are an Eco-Friendly Choice

Tin boxes have long been favored in packaging due to their durability, aesthetic appeal, and protective qualities. Unlike many single-use packaging materials, tin boxes offer several environmental benefits right from the start:

- Reusability: Tin boxes are often repurposed after their initial use, whether for storage or decoration, reducing waste compared to disposable packaging.

- Recyclability: Tin is highly recyclable, and tin boxes can be melted down and reused repeatedly without losing quality, making them a sustainable option.

- Durability: The longevity of tin boxes reduces the need for frequent replacement, minimizing the resources consumed for packaging over time.

However, the industry is now going beyond these inherent advantages, focusing on innovative ways to further reduce environmental impact throughout the production and supply chain.

Eco-Friendly Innovations in Tin Box Manufacturing

Huaiyang Metal Manufacture and other leading companies in the tin packaging industry are exploring several ways to make their products more eco-friendly. These innovations include:

1. Sustainable Sourcing of Materials

The raw materials used to manufacture tin boxes are crucial in determining their environmental footprint. Tin is a finite resource, and mining it can have ecological consequences. To address this, companies like Huaiyang Metal Manufacture are turning to more sustainable sources for their raw materials, such as:

- Recycled tin: Using recycled tin in manufacturing processes reduces the need for new mining operations and lowers energy consumption. Recycled materials also cut down on greenhouse gas emissions, aligning with global sustainability goals.

- Ethical sourcing: Ensuring that tin is sourced from environmentally responsible and conflict-free regions is another step toward minimizing the environmental and social impact of tin box manufacturing.

2. Energy-Efficient Manufacturing Processes

Manufacturing processes can contribute significantly to the environmental impact of packaging production. To minimize their carbon footprint, companies like Huaiyang Metal Manufacture are investing in energy-efficient technologies and processes. These include:

- Energy-efficient machinery: The use of modern, high-efficiency machinery reduces energy consumption during the production of tin boxes.

- Renewable energy sources: Some manufacturers are incorporating renewable energy, such as solar or wind power, into their production facilities to further cut down on greenhouse gas emissions.

- Reduced water consumption: By optimizing production processes, manufacturers are also reducing water usage, which is essential for preserving this vital resource.

3. Non-Toxic and Biodegradable Coatings

Traditionally, tin boxes have been coated with lacquers or other materials to enhance their durability and appearance. However, many conventional coatings contain harmful chemicals that can leach into the environment. To counter this, Huaiyang Metal Manufacture is developing non-toxic, biodegradable coatings that do not compromise the quality or safety of the tin boxes while being more environmentally friendly.

These eco-friendly coatings are free from volatile organic compounds (VOCs) and other pollutants, ensuring that the entire packaging process— from manufacturing to disposal— is less harmful to the environment.

4. Design for Reusability and Recyclability

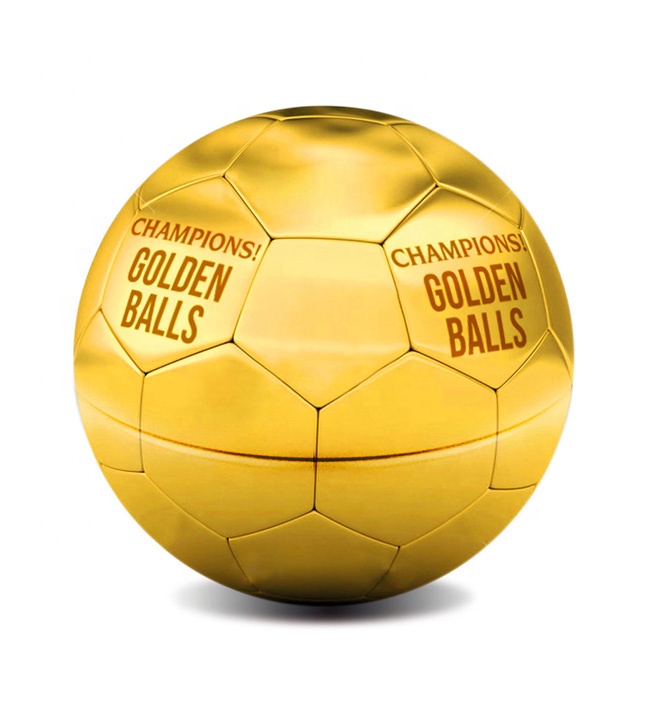

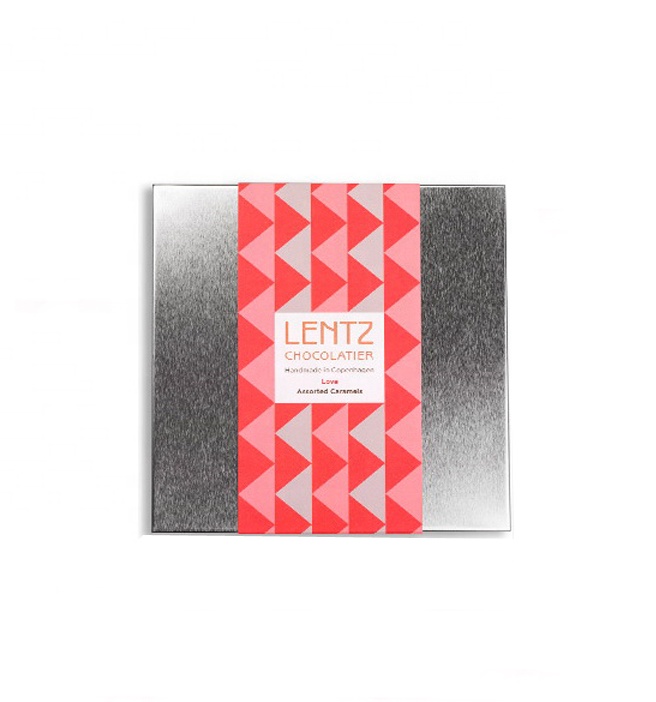

Eco-friendly tin box manufacturers are focusing on product designs that encourage reusability and make recycling easier. Huaiyang Metal Manufacture is designing tin boxes that are both durable and attractive, encouraging consumers to repurpose them after their initial use. In addition, the company is ensuring that the design and materials used in their tin boxes are easily separable and recyclable, reducing the effort and energy required for recycling.

Packaging Trends Driving Eco-Friendly Innovations

The growing demand for eco-friendly packaging is being driven by several key trends, including:

-

Consumer Demand for Sustainability: Consumers are more aware than ever of the environmental impact of their purchasing decisions. Many now prefer brands that offer sustainable packaging solutions. This trend is especially prevalent in the food, cosmetics, and gift industries, where premium, eco-friendly packaging adds value to the product.

-

Regulatory Pressures: Governments around the world are implementing stricter environmental regulations aimed at reducing plastic waste, lowering carbon emissions, and promoting recycling. Manufacturers are under increasing pressure to comply with these regulations by adopting sustainable practices.

-

Corporate Sustainability Goals: Many companies across industries have set ambitious sustainability goals, including reducing their carbon footprint, transitioning to zero waste, and using 100% recyclable or biodegradable packaging. Tin box manufacturers must align their products with these goals to remain competitive.

Challenges in Implementing Eco-Friendly Practices

While the transition to eco-friendly packaging solutions is beneficial, it comes with its own set of challenges. For tin box manufacturers, these challenges include:

-

Cost: Implementing sustainable practices such as using recycled tin, energy-efficient machinery, and non-toxic coatings can increase production costs. However, as demand for eco-friendly packaging grows, economies of scale can help reduce these costs over time.

-

Supply Chain: Ensuring a steady supply of recycled or sustainably sourced materials can be difficult, especially in regions where infrastructure for recycling and ethical sourcing is not fully developed.

-

Consumer Perception: Some consumers may perceive eco-friendly packaging as being of lower quality or less durable than traditional packaging. Manufacturers need to ensure that their products maintain the same level of quality while promoting their environmental benefits.

Comparison of Peer Products: Huaiyang Metal Manufacture vs. Competitors

When comparing Huaiyang Metal Manufacture’s eco-friendly tin box products to those of other manufacturers, it’s clear that we lead the industry in innovation and sustainability. Below is a comparison of key features:

|

Feature |

Huaiyang Metal Manufacture |

Competitor A |

Competitor B |

|---|---|---|---|

|

Material Sourcing |

Uses recycled tin and ethically sourced materials | Primarily uses virgin tin, limited recycling efforts | Some recycled tin, but lacks ethical sourcing certification |

|

Energy Efficiency |

Advanced energy-efficient manufacturing with renewable energy integration | Standard machinery with no focus on energy reduction | Moderate energy efficiency, no use of renewables |

|

Eco-Friendly Coatings |

Non-toxic, biodegradable coatings | Conventional coatings with VOCs | Limited eco-friendly coating options |

|

Design for Reusability |

Highly durable and attractive designs to encourage reuse | Basic designs, limited focus on reusability | Some focus on design, but lacks durability |

|

Cost-Effectiveness |

Competitive pricing for eco-friendly products | Lower cost, but environmentally harmful practices | Higher cost with moderate environmental efforts |

Why Choose Huaiyang Metal Manufacture?

At Huaiyang Metal Manufacture, we are committed to leading the industry in eco-friendly tin box manufacturing. Here’s why our solutions stand out:

- Sustainable Materials: We prioritize the use of recycled tin and responsibly sourced materials, ensuring our products have a minimal environmental footprint.

- Energy-Efficient Manufacturing: Our investment in energy-efficient machinery and renewable energy sources reduces our carbon footprint while delivering high-quality products.

- Non-Toxic Coatings: Our innovative, eco-friendly coatings provide long-lasting protection without harming the environment.

- Focus on Reusability: Our attractive and durable designs encourage customers to reuse their tin boxes, further reducing waste.

Conclusion

As the world moves toward a more sustainable future, tin box manufacturers are stepping up to the challenge by adopting eco-friendly practices. From sourcing recycled materials to designing reusable packaging, companies like Huaiyang Metal Manufacture are paving the way for a greener packaging industry. By focusing on sustainability, innovation, and quality, we are helping to meet the growing demand for eco-friendly packaging solutions while reducing our impact on the environment.

With eco-friendly materials, energy-efficient processes, and a commitment to sustainability, Huaiyang Metal Manufacture is your trusted partner for premium, environmentally responsible tin packaging. Contact us today to learn more about our products and how we can support your sustainability goals.