1. Understand the Purpose

The first step in designing a tin box is to clearly define its purpose. Are you creating packaging for a luxury item, a practical storage solution, or perhaps a promotional gift? Understanding the intended use of the tin box helps in determining the appropriate size, shape, and materials. For instance, a tin intended for storing delicate teas might include a double-lid design to preserve freshness, while one designed for promotional purposes might focus more on eye-catching aesthetics.

2. Select the Right Materials

While most tin boxes are made from tin-plated steel, the thickness and grade of the material can vary depending on the box’s requirements. We provides guidance on selecting the best material based on the box’s intended use, durability needs, and budget. For food-grade containers, it’s crucial to use materials that comply with food safety regulations, ensuring that the tin does not alter the food’s flavor or pose health risks.

3. Choose a Shape and Size

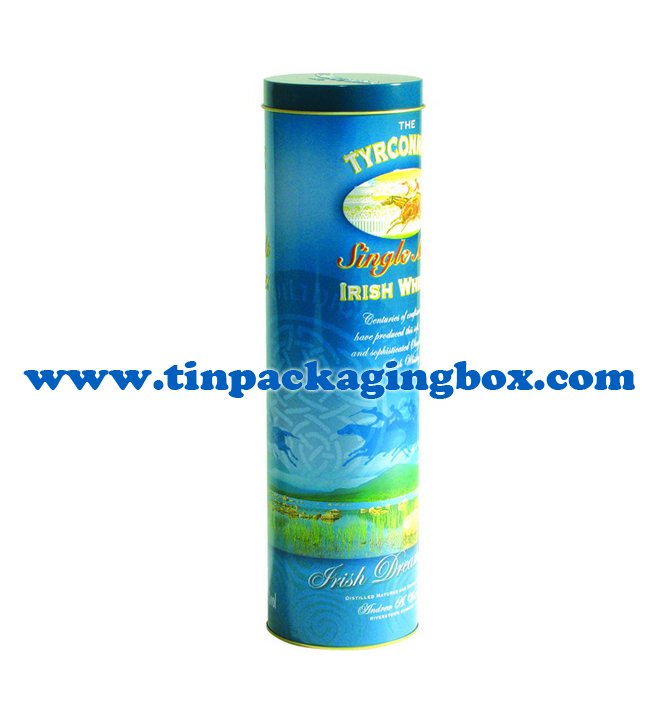

Tin boxes come in a variety of shapes and sizes, from traditional rectangular or square formats to more innovative heart-shaped or round designs. The choice of shape and size should reflect the product’s dimensions and the brand’s image. Custom shapes might be more memorable and can set a product apart in a competitive market. Huaiyang Metal Manufacture offers a range of standard dies and also supports custom dies for unique shapes.

4. Design Engaging Graphics

The artwork on a tin box is not just about attractiveness; it communicates the brand’s message and appeals directly to the consumer’s senses. When designing graphics for a tin box, consider elements that reflect the brand’s identity, such as logos, color schemes, and typographic details. It’s also important to consider the printing techniques available. We utilizes advanced printing technologies such as offset lithography, which allows for vibrant, detailed designs that are durable and scratch-resistant.

5. Consider Functional Enhancements

Adding functional elements can greatly enhance the user experience and functionality of a tin box. Features such as embossing can provide a tactile element that enhances grip and adds a premium feel. Other functional enhancements might include hinges for easy opening, clasps for secure closure, or inserts that hold the product in place inside the tin. Huaiyang Metal Manufacture can incorporate these elements during the design phase to ensure that they blend seamlessly with the overall design.

6. Prototype and Test

Before moving to mass production, it is essential to prototype and test the tin box design. Prototyping helps identify any design flaws or functional issues that might not be apparent in the initial drawings. Testing the prototype under different conditions can also ensure that the tin box meets all functional requirements and withstands transport and handling. Huaiyang Metal Manufacture supports this process with samples and small batch trials to guarantee that the final product is both aesthetically pleasing and robust.

7. Sustainability Considerations

Sustainability is increasingly important in product packaging. Designing a tin box with sustainability in mind can appeal to eco-conscious consumers. Tin is highly recyclable, and designing for reusability can further enhance the environmental appeal of the product. Considerations such as minimal use of non-recyclable components and creating designs that consumers might want to keep and reuse can contribute to a product’s sustainability profile.

Designing a tin box involves careful consideration of the product’s purpose, the choice of materials, functional requirements, and brand representation. With its expertise in metal manufacture and packaging design, Huaiyang Metal Manufacture is a valuable partner in creating tin boxes that not only meet practical and aesthetic standards but also resonate with consumers.